Fabrication

If you dream it, we can build it. From full-blown customs to irreplaceable restoration parts, we can fabricate the most complicated of panels for you. We have many tools on hand, like an English wheel or shrinker/stretcher, that allows to form many different shapes. We'd love to build something unique for you! Why blend in when you can stand out?

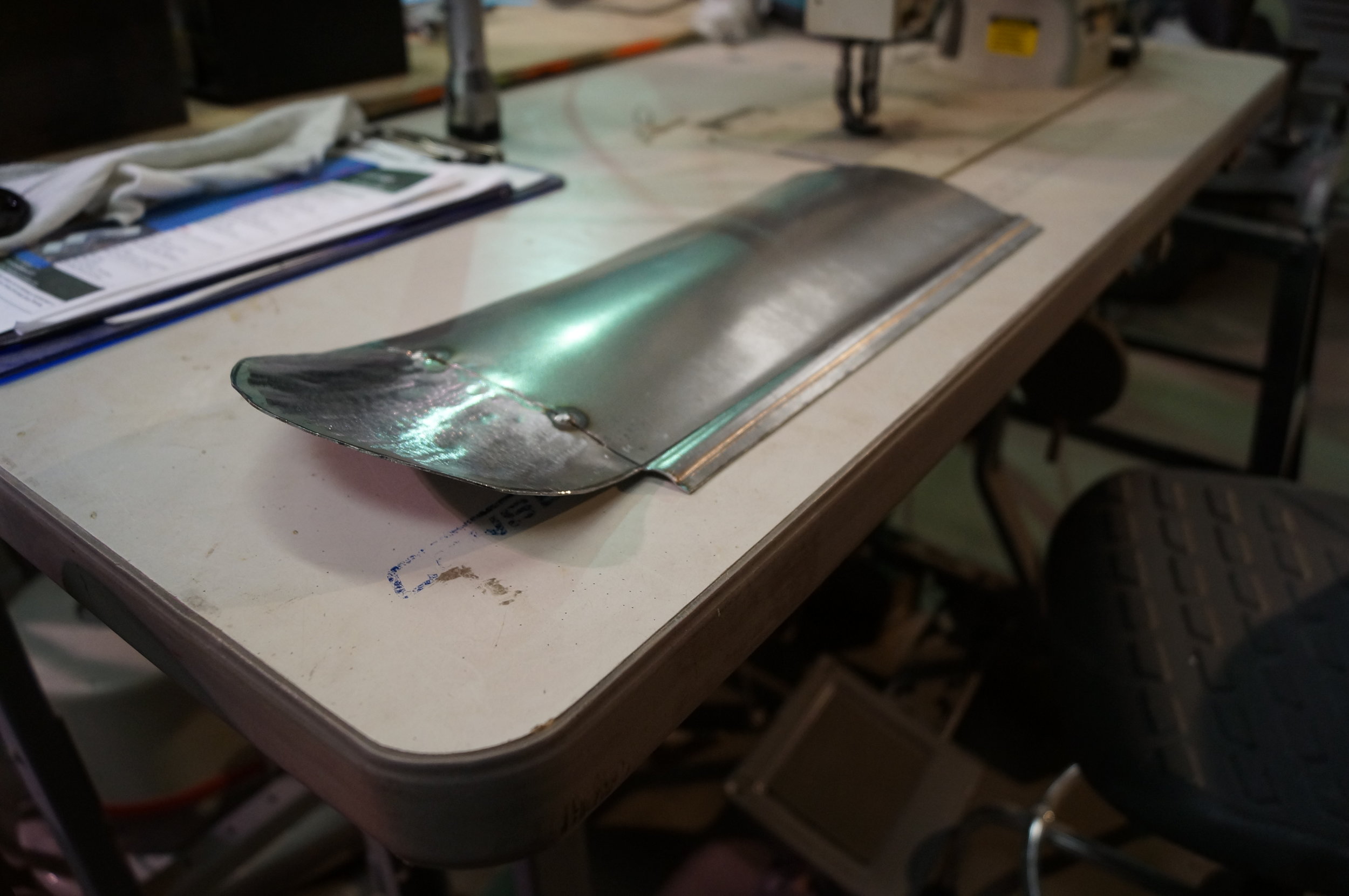

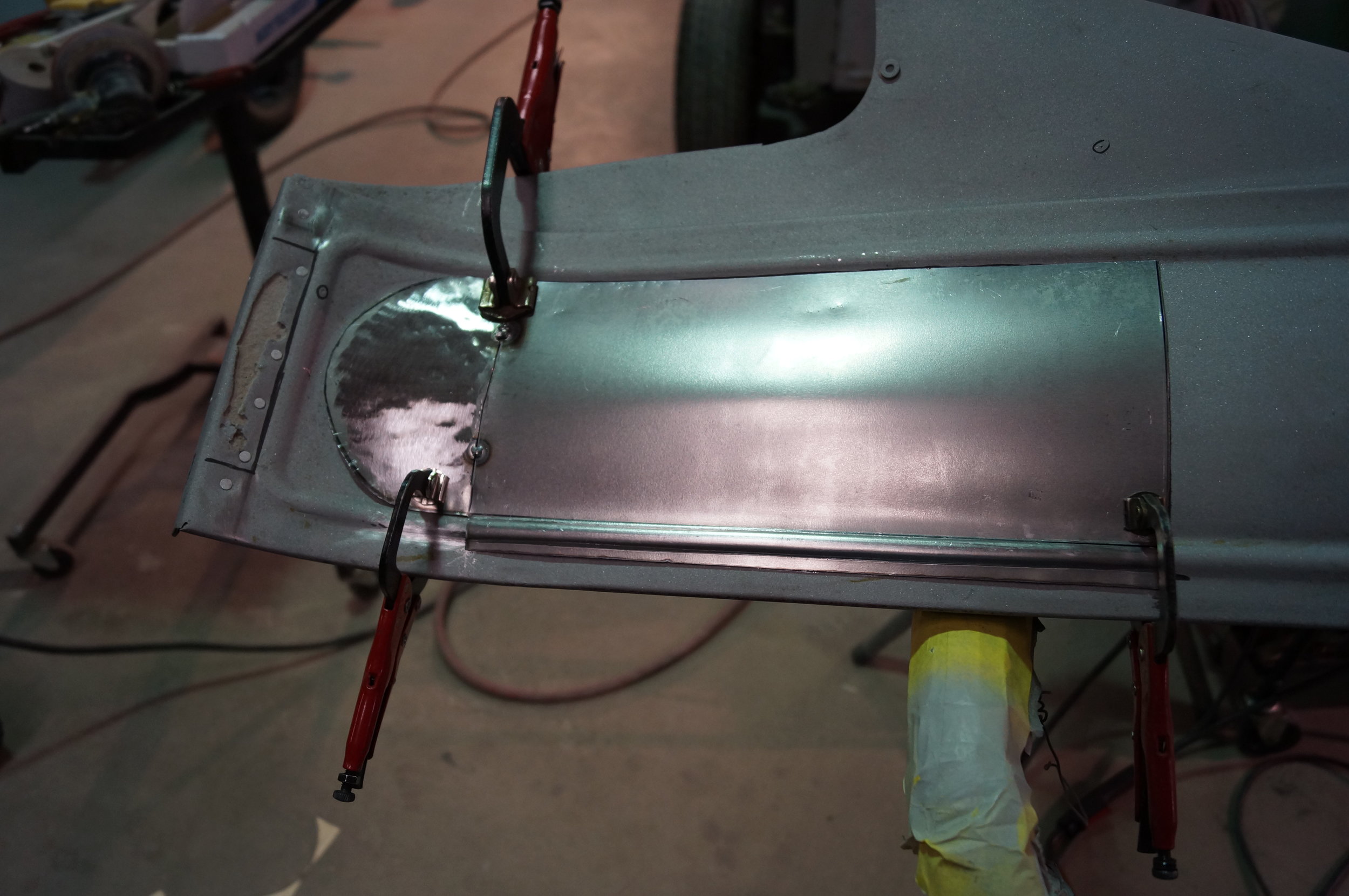

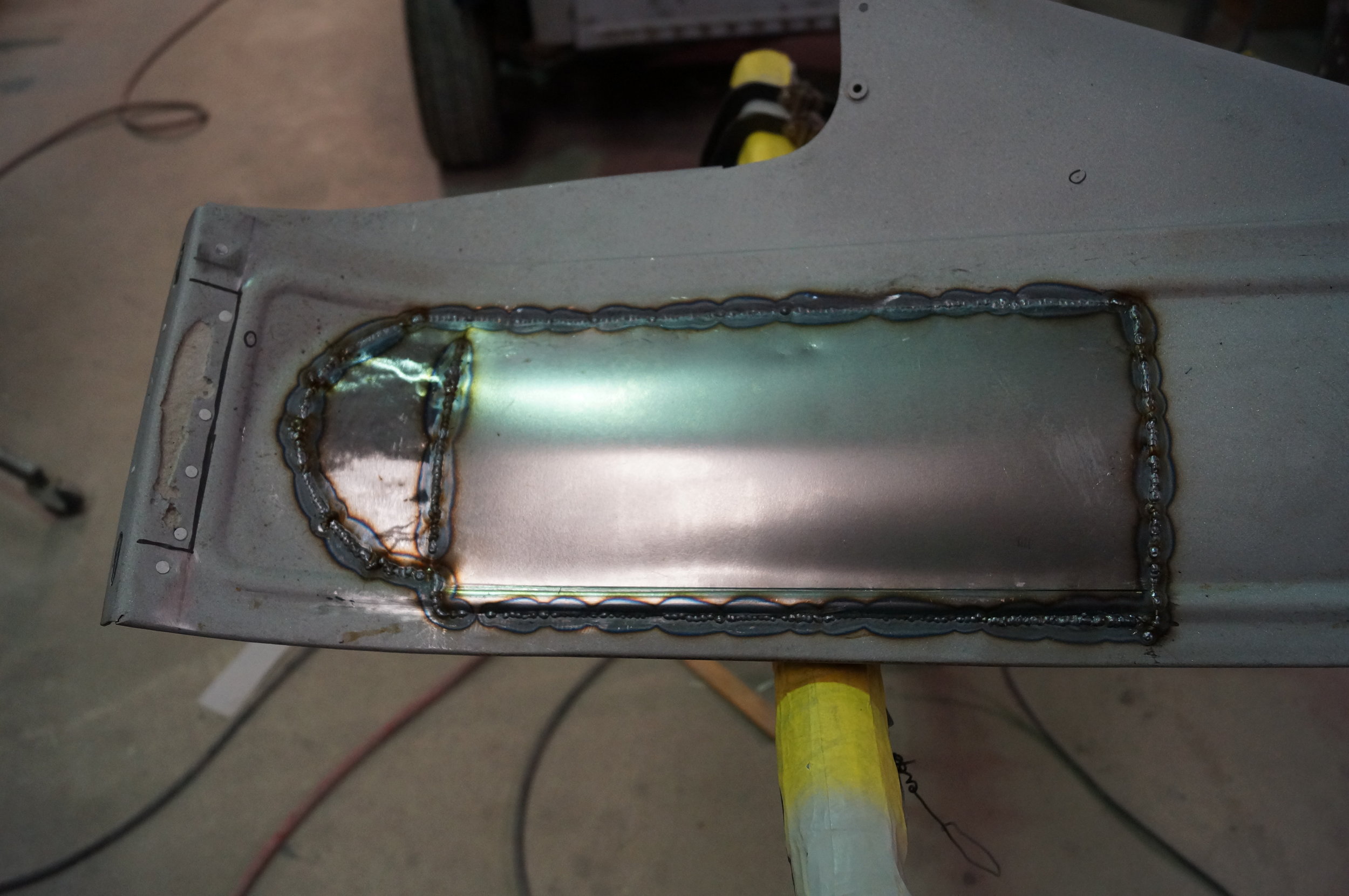

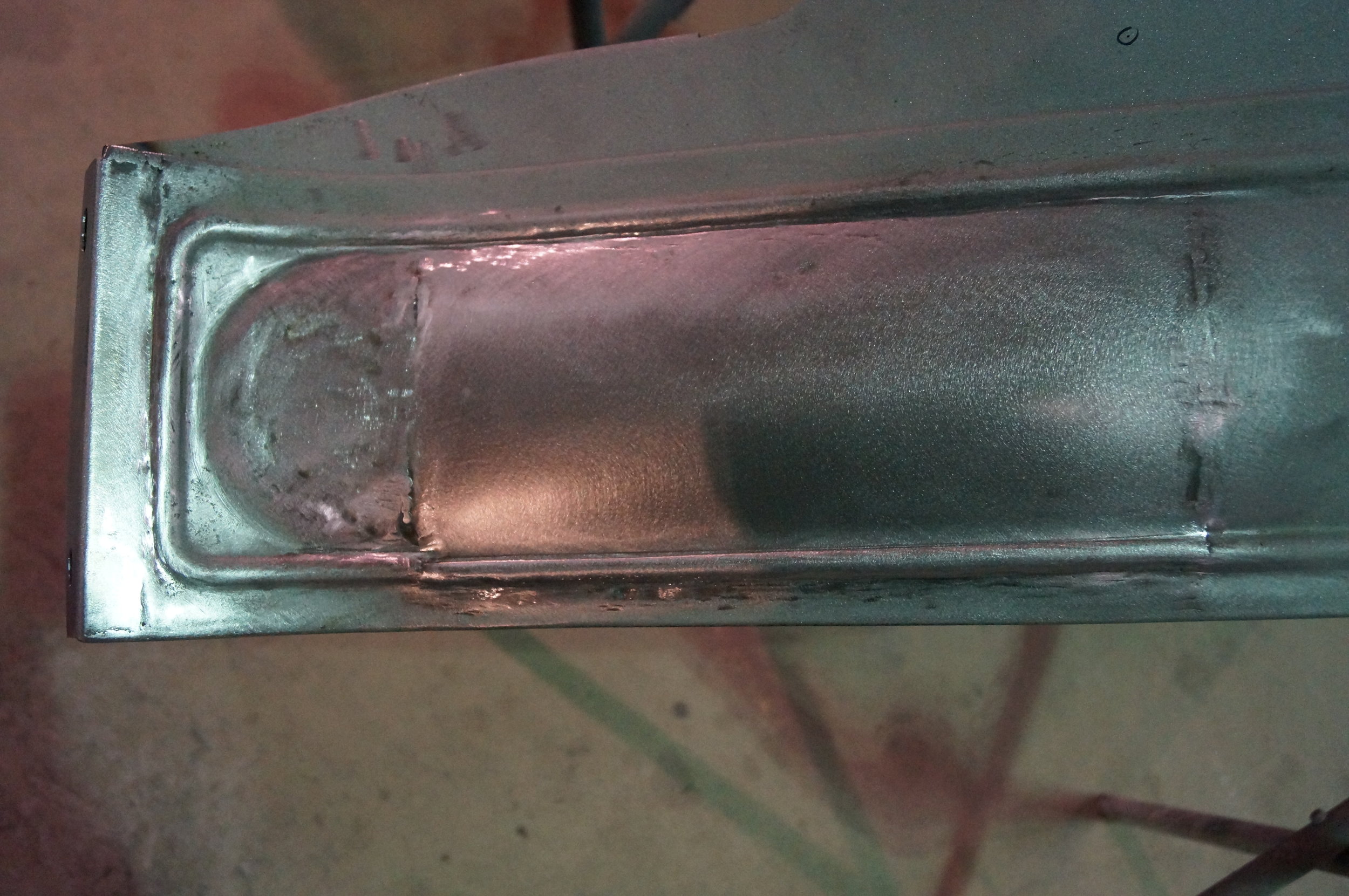

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

RH Front Fender Rust Repair

A lot of the sheet metal fabrication that we perform involves rust repair and panel replacement. As you can see from the pictures above, this rust occurred on a 1923 Detroit Electric fender. Not exactly a fender you can call up an order new or in reproduction form. A patch had to be made to properly repair this panel. Not only did the contour (or crown) have to match correctly, but the bead. After the panel is fully welded in, and the welds have been ground down, our craftsman will go over the panel with a hammer and dolly, and a file, to make the patch panel fit even more seamlessly to the original panel.

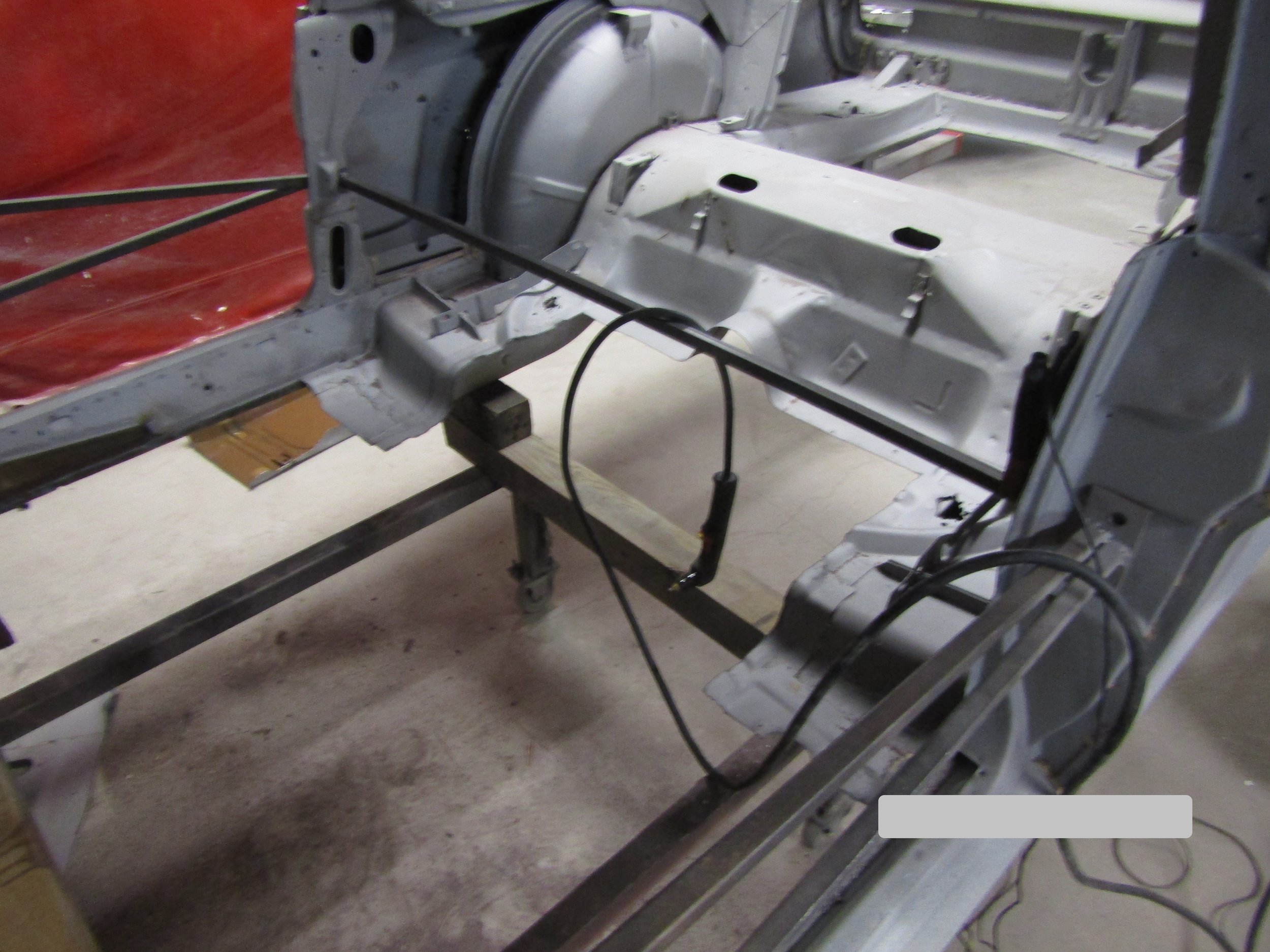

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Full Floor Pan Replacement

Tackling a project like this Mustang pictured above isn't for the faint of heart. It takes a lot of experience and knowledge to properly replace large panels like this. Not only are we concerned how the floor is going to fit, but the doors, trunk, and fenders, too. By the time all of our welding and grinding has been performed, the Mustang will have regained its structural integrity, and have properly opening and closing doors and trunk lid, with the proper gaps to match.

1967 Datsun 1600 Roadster-- Trunk Floor Pan Replacement

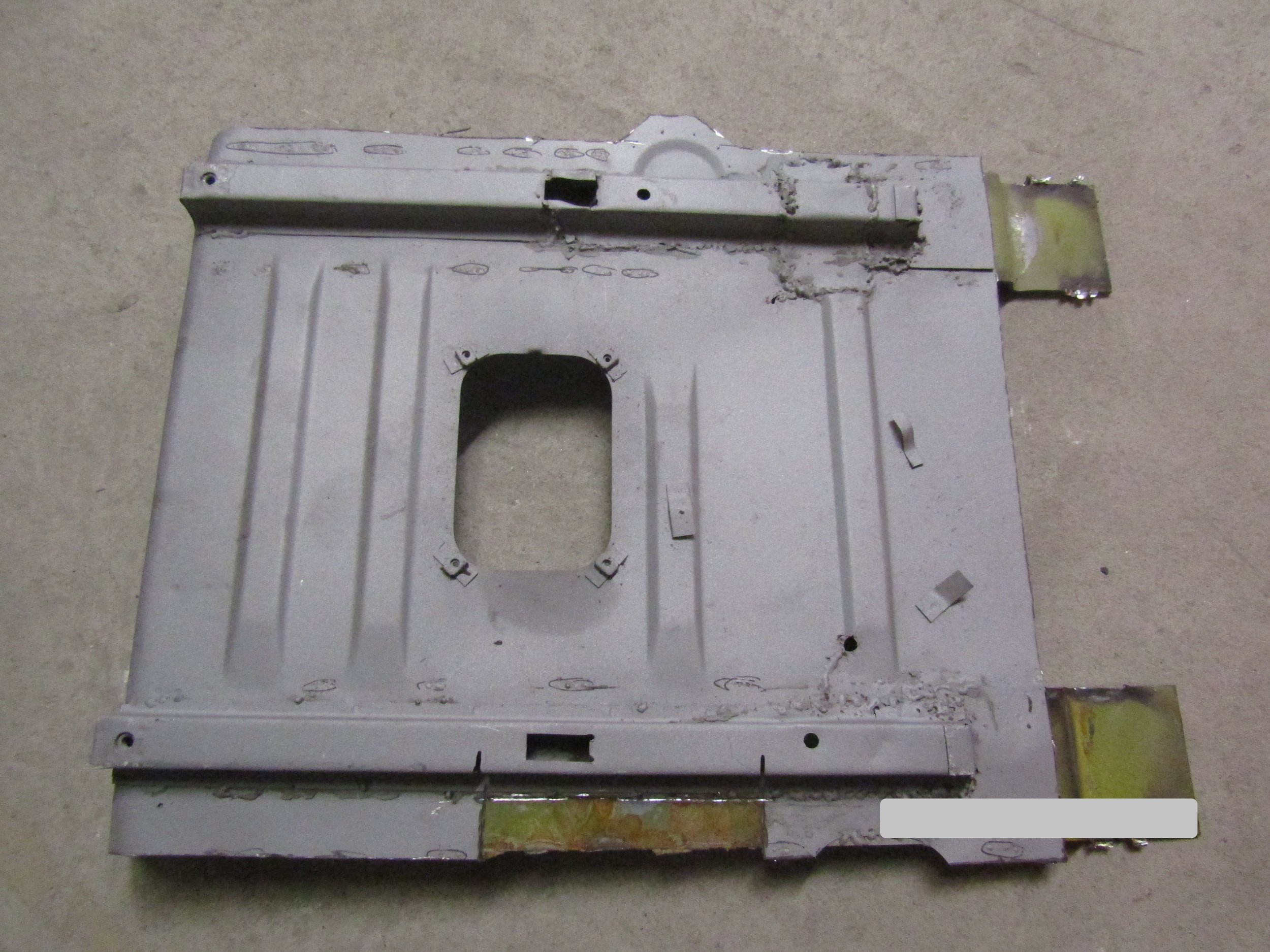

Very POOR welds and patch panel fitment. Cracks can be seen in metal.

Very POOR welds and patch panel fitment.

Thick, steel plates have been added for reinforcement. If repaired properly, this would not have been necessary.

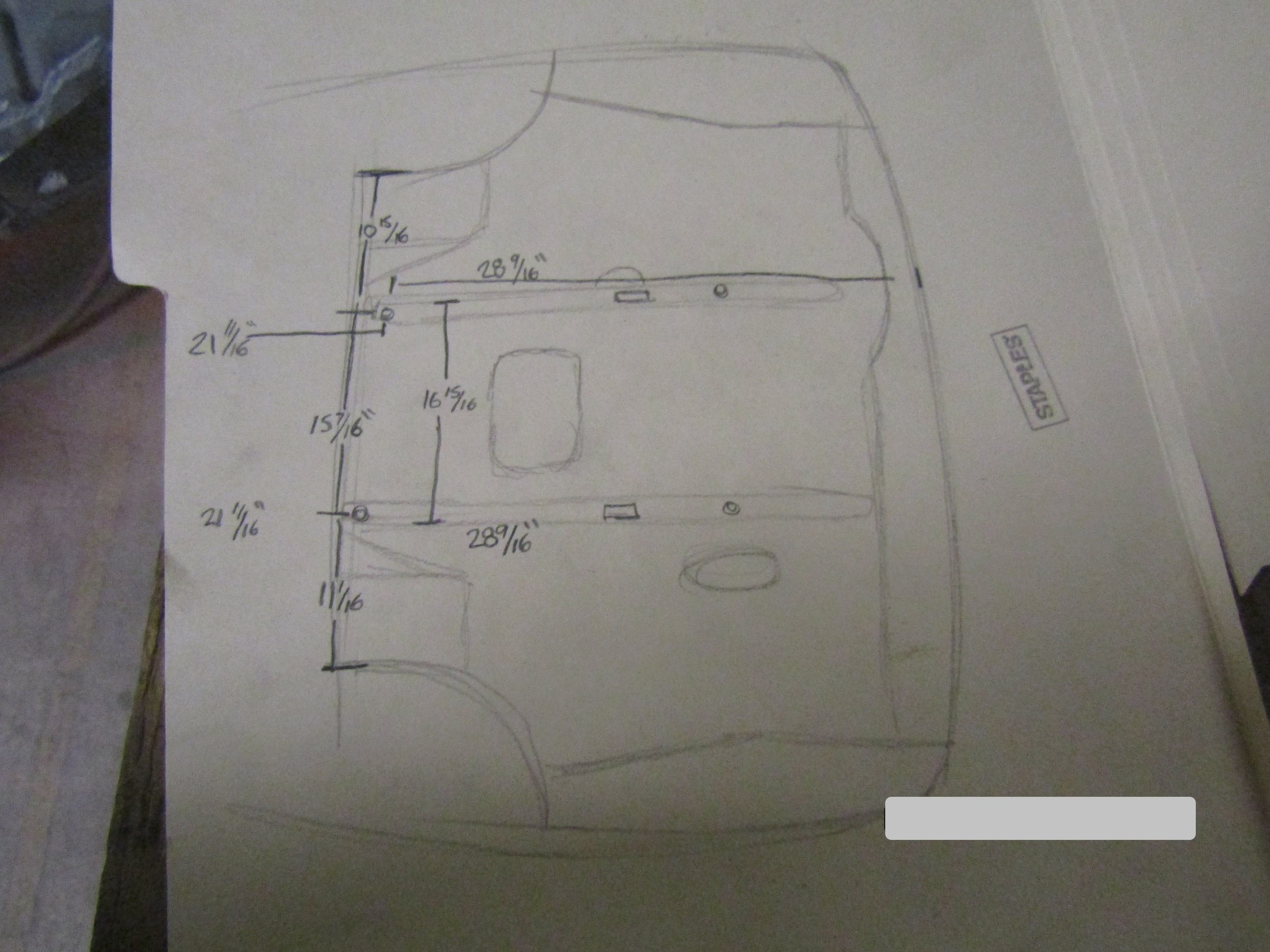

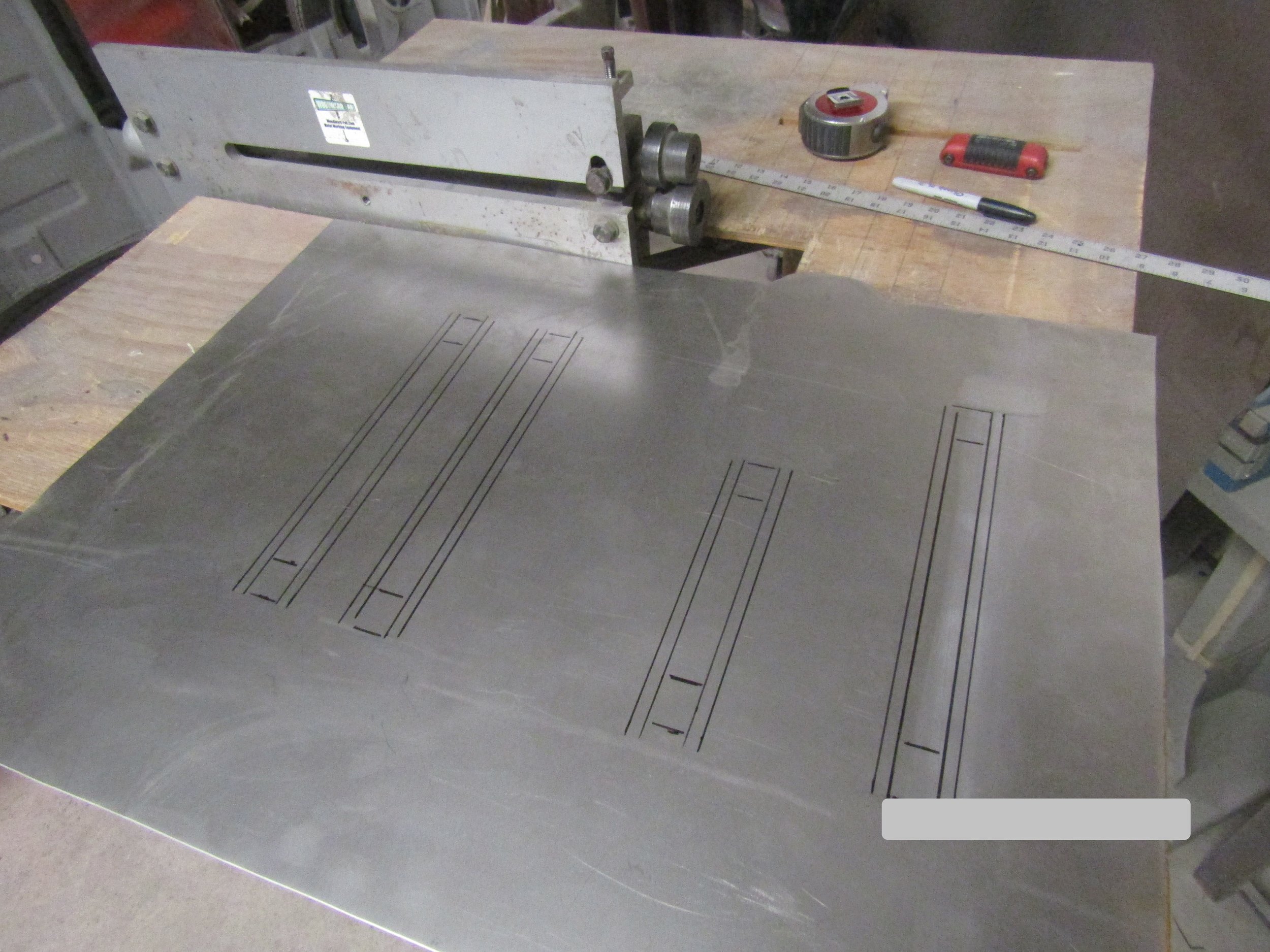

Taking measurements.

Cutting out area to be replaced.

Thick, steel plates have been added for reinforcement. If repaired properly, this would not have been necessary.

Very POOR welds.

Using bead roller to form beads in new panel.

Using bead roller to form beads in new panel.

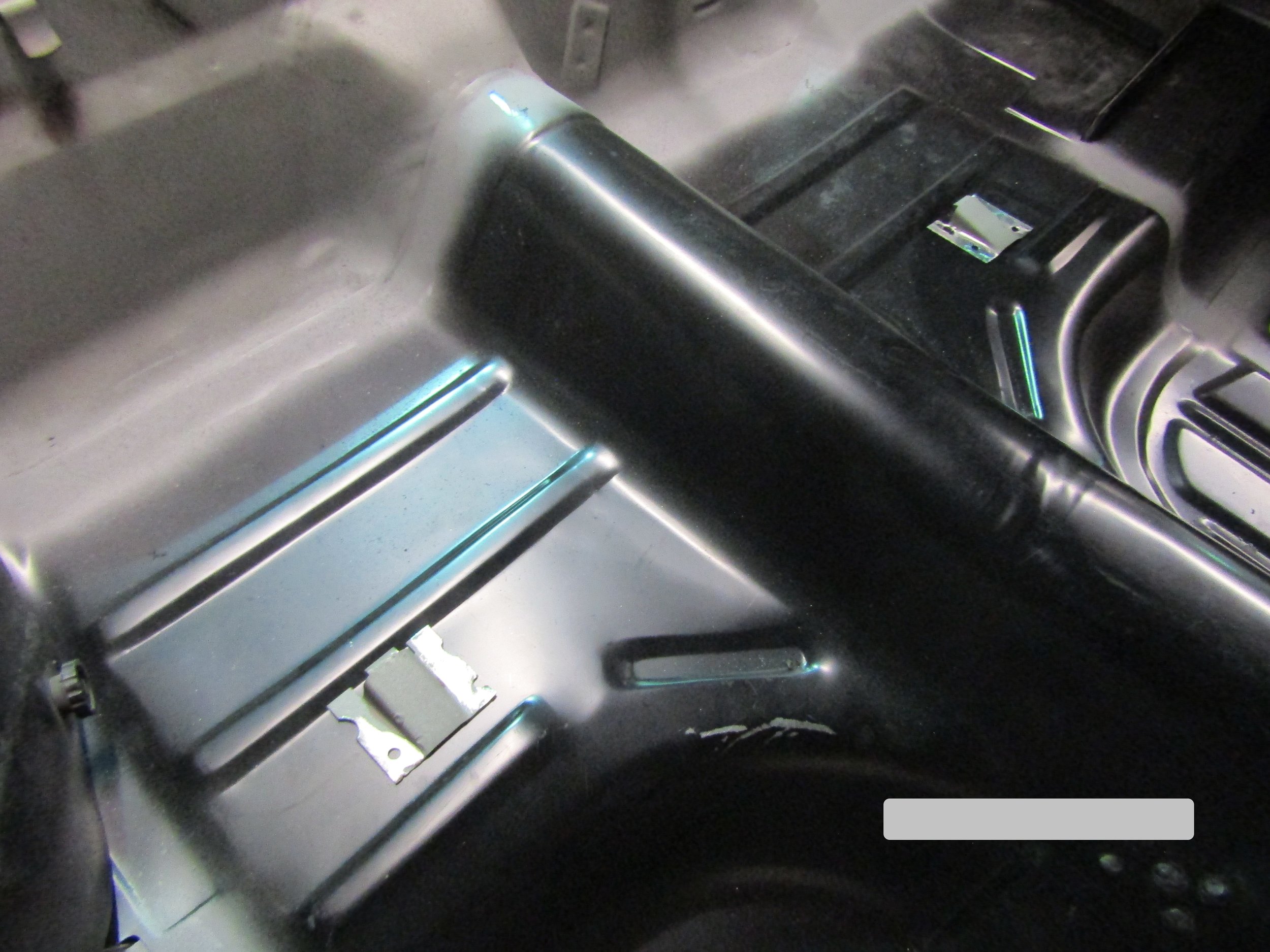

Beads have been rolled into panel. Will use hammer and dolly to create more prominent lines.

Beads have been rolled into panel. Will use hammer and dolly to create more prominent lines.

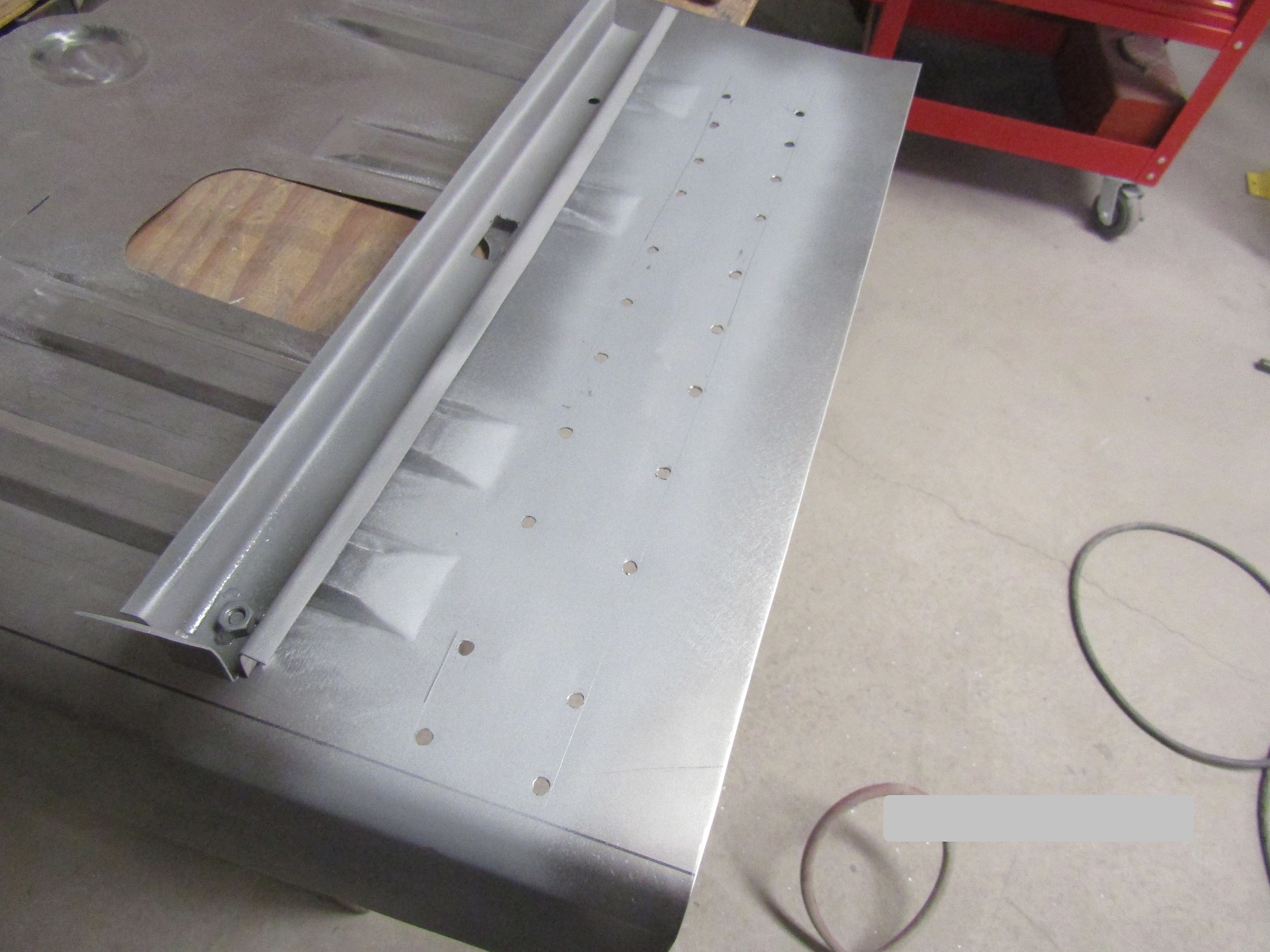

Used sheet metal brake to bend new U-channel support braces.

Used sheet metal brake to bend new U-channel support braces.

Used sheet metal brake to bend new U-channel support braces.

Applied weld-thru primer before installing U-channel support braces.

Applied weld-thru primer before installing U-channel support braces.

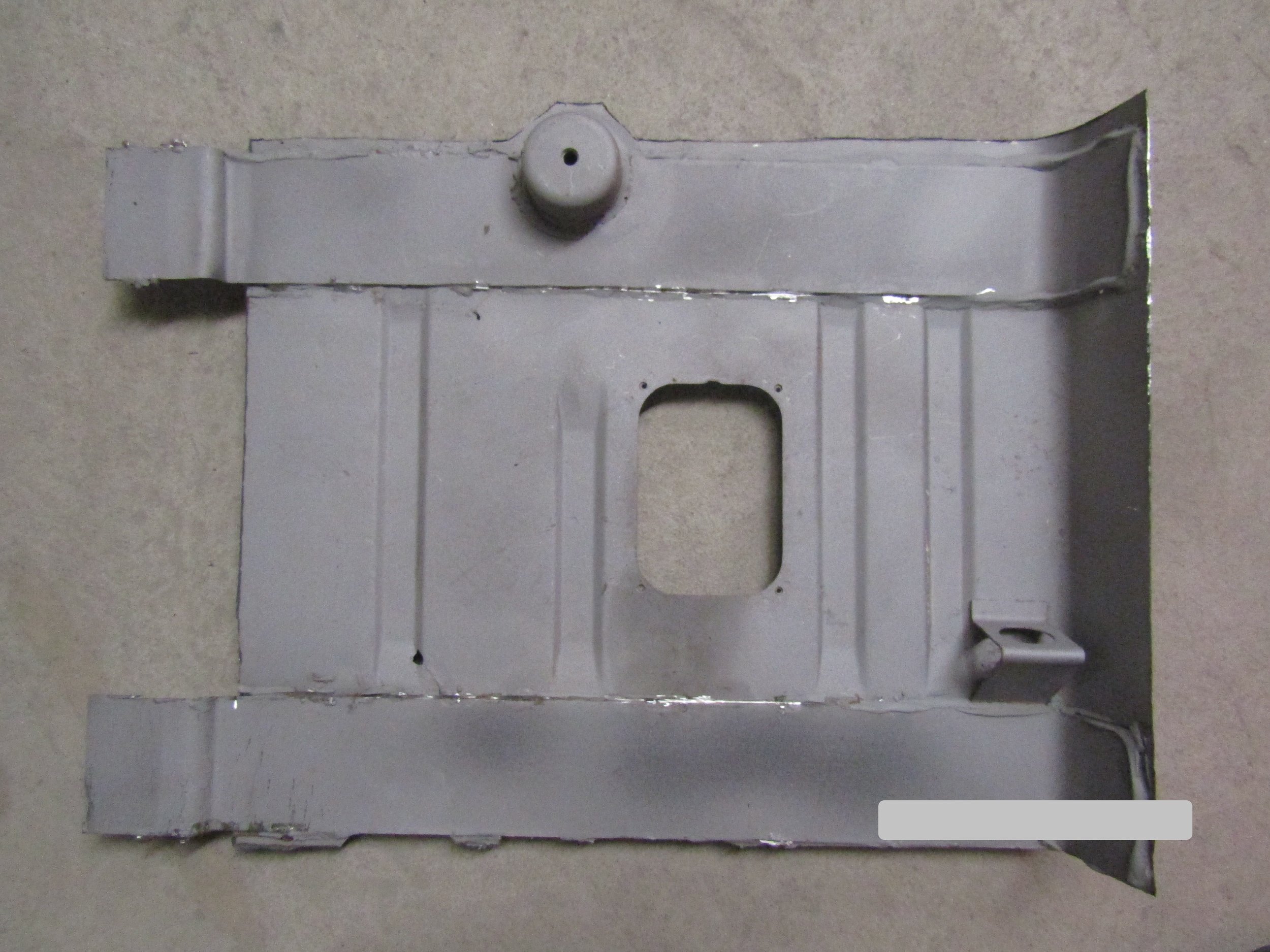

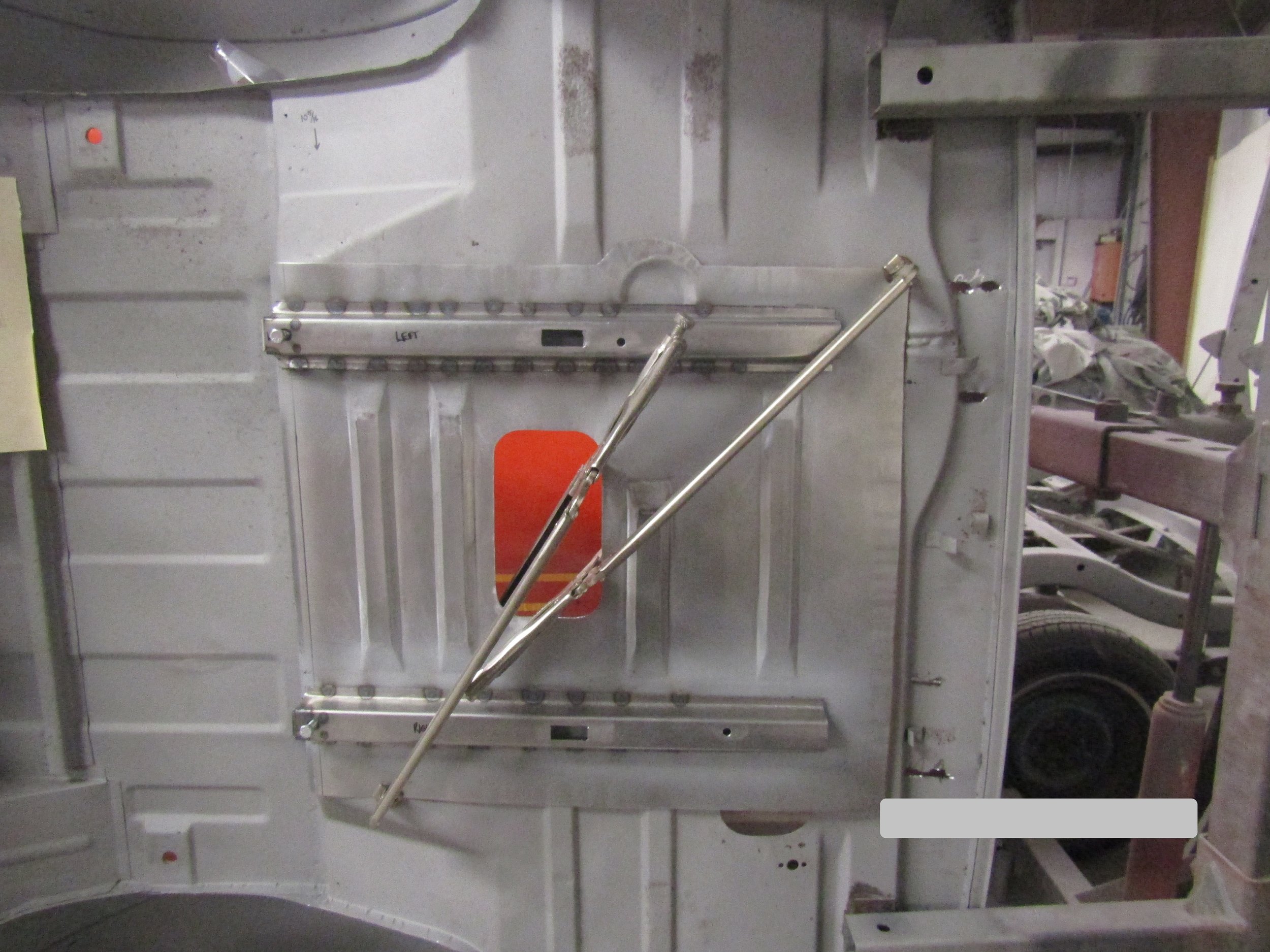

Test fitting patch panel.

Test fitting. Ensuring beads line up.

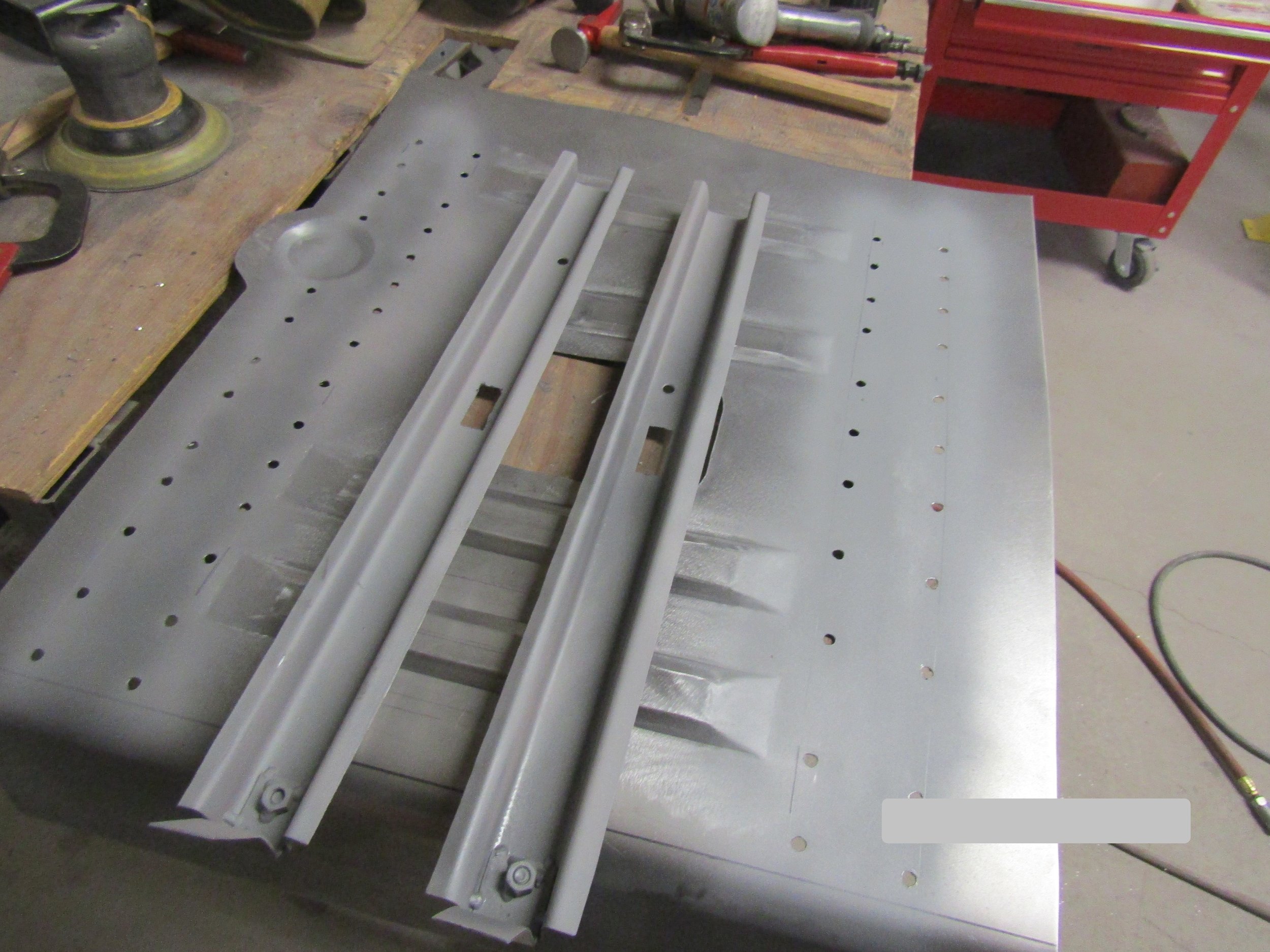

Aligning panel and butt welding into place for seamless finish when welds and ground smooth.

Aligning panel and butt welding into place for seamless finish when welds and ground smooth.

Fully butt welded into place for seamless finish when welds and ground smooth.

Welds ground smooth.

Self-etch primer applied temporarily to check for correctness of repair.

This 1967 Datsun 1600 Roadster trunk floor is another example of a poor repair. Just look at those welds! Not only do they look horrendous, but they're not strong. On the inside of the trunk floor, you can see where they added long, thick steel plates to help reinforce their repair. Had they repaired it properly, there would've been no need for additional supports. We ended up cutting out the floor, and made a new one completely from scratch, following the old measurements exactly. After the car is painted, you'll never be able to tell that the trunk floor was replaced. Same couldn't have been said had we left the previous repair.